When undertaking any engineering project, selecting the right bearings is crucial to ensuring the performance, longevity, and reliability of your machinery. Bearings play a vital role in reducing friction, supporting loads, and enabling smooth motion. Whether you're working on mechanical engineering systems or other industrial applications, choosing the appropriate engineering bearings can make all the difference. We have put together a guide to help you choose.

When undertaking any engineering project, selecting the right bearings is crucial to ensuring the performance, longevity, and reliability of your machinery. Bearings play a vital role in reducing friction, supporting loads, and enabling smooth motion. Whether you're working on mechanical engineering systems or other industrial applications, choosing the appropriate engineering bearings can make all the difference. We have put together a guide to help you choose.

Understanding the Types of Bearings

There are various types of bearings used for engineering projects, each designed for specific functions. Knowing the differences between these types will help you make an informed decision. Below are some of the commonly used mechanical engineering bearings in the industry:

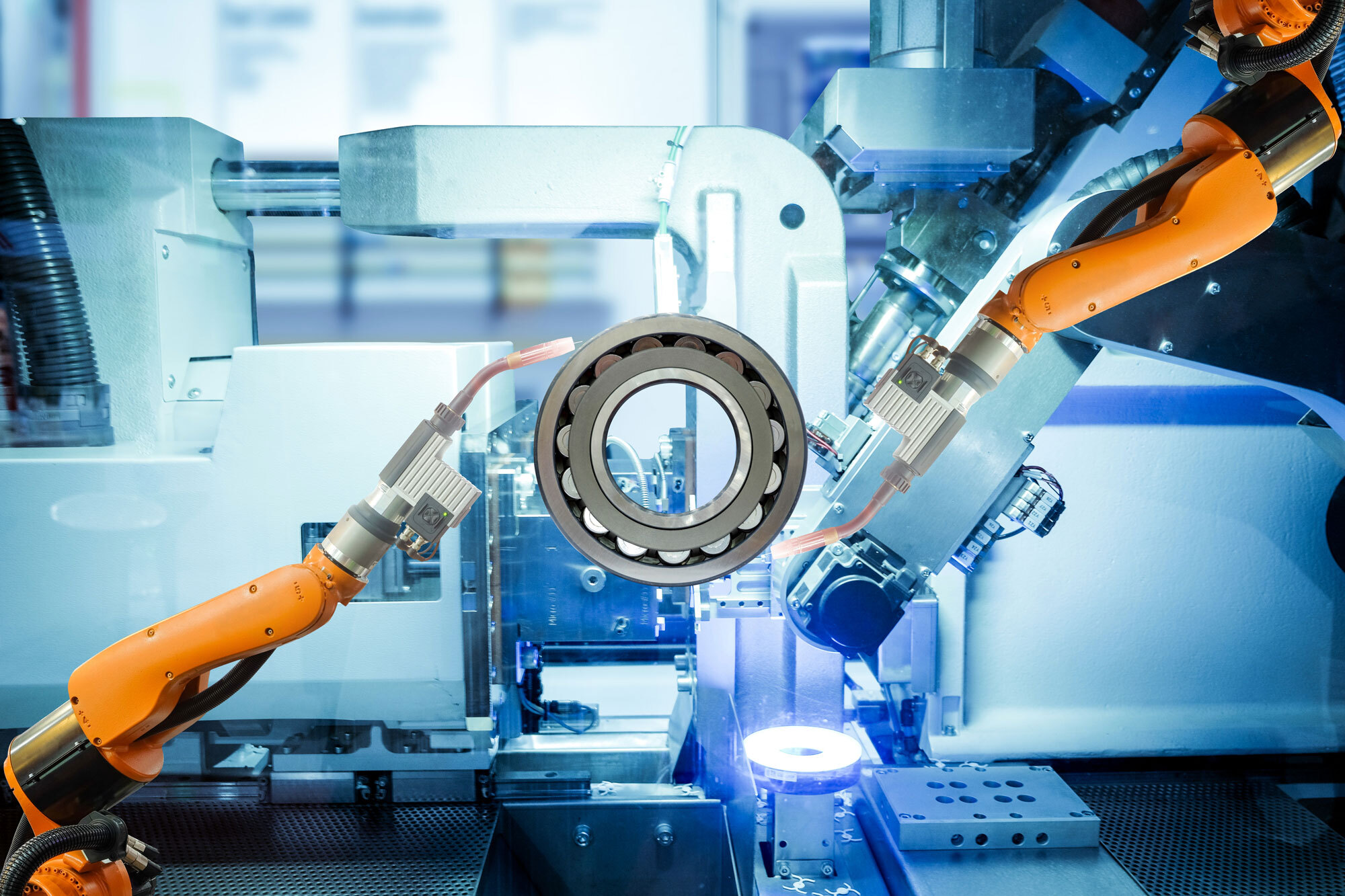

Spherical Roller Bearings

One of the most versatile engineering bearings, Spherical Roller Bearings are designed to accommodate both radial and axial loads. Their self-aligning feature makes them ideal for use in applications where shaft misalignment is a concern, such as in large machinery, electric motors, and pumps. We stock these bearings in a wide range of sizes and configurations.

Tapered Roller Bearings

Taper Roller Bearings are specifically designed to accommodate a combined simultaneously acting radial and axial loads, but unlike spherical roller bearings, they are best suited for applications with high radial loads and where precise axial control is necessary. These engineering bearings are used in vehicle wheel hubs, gearboxes, and conveyor systems. Their ability to handle combined loads and their capacity for high-speed performance make them a crucial part of many projects.

Angular Contact Ball Bearings

Angular contact ball bearings are designed to handle both radial and axial loads but with an emphasis on supporting axial loads. They are commonly used in high-precision applications such as machine tool spindles, pumps, and motors. These bearings come in different configurations, including Single-Row, Double-Row, and also the Four Point Contact Ball Bearing.

Deep Groove Ball Bearings

Another popular choice are, Deep Groove Ball Bearings. They are versatile and commonly used in low- to medium-speed applications. They are particularly beneficial when space constraints are a concern, thanks to their compact design. They can handle radial and axial loads in both directions making them useful for use in electrical motors.

Needle Bearings

Needle Roller Bearings are designed for applications where there is limited space and where high load capacity is required. These engineering bearings are ideal for use in automotive transmissions, compact machinery, and agricultural equipment. Their, thin rollers allow them to support high radial loads despite their small size, making them excellent for tight spaces.

Thrust Bearings

For applications where there are primarily axial loads, Thrust Bearings are the best option. These bearings are used in applications such as automotive clutches, rotary tables, and power steering systems. Thrust ball bearings are ideal for handling axial loads in one direction, while tapered or spherical thrust bearings can handle both axial and radial loads simultaneously.

Key Factors to Consider When Choosing Engineering Bearings

Selecting the right mechanical engineering bearings involves more than just picking a category. Several factors must be considered to ensure the bearings meet the requirements of your project. Below are some essential considerations to keep in mind when selecting bearings.

Load Type and Direction

The first step in choosing engineering bearings is understanding the type of load your application will bear. Some bearings are designed to handle radial loads, axial loads, or both. For instance, Spherical Roller and Tapered Roller bearings are designed to support both load types.

Speed and Temperature Conditions

High-speed applications require bearings that can operate at greater RPMs without generating heat. Deep Groove Ball bearings are ideal for high-speed applications, while Angular Contact Ball bearings offer improved axial load handling for precision machinery. Also, consider the operating temperature, as certain materials can handle heat better than others.

Space and Mounting Constraints

Size is often a critical factor when selecting an engineering bearing. Some applications may require bearings that fit into limited spaces, such as in compact machinery or automotive components. Deep Groove Ball bearings are perfect for such constraints due to their compact size.

Environment and Application

Consider the environment in which the bearing will operate. Bearings used in harsh conditions need to be more resilient. Choosing the right mechanical engineering bearings that are sealed or coated for protection will help prolong the life of the bearing in challenging environments.

Final Thoughts

Selecting the right bearings for your engineering project is essential for ensuring optimal performance. Understanding the different types of mechanical engineering bearings is the first step in making an informed decision. Keep in mind the factors we have mentioned to help guide you in choosing engineering bearings that meet the specific needs of your application.

At Quality Bearings Online, we offer a wide range of bearings for various engineering projects. If you need any further information or advice, contact our friendly support team today.