Spindle bearing failure in CNC machines can be extremely frustrating, as it can result in unexpected machine downtime. This is costly not only to fix, but it also disrupts production schedules and affects overall efficiency. Reverse engineering this and identifying symptoms of a ‘bad’ spindle bearing can help prevent failures and reduce expensive repairs. Read on to learn more about the 8 main reasons why spindle bearings fail in CNC machines, what causes these issues, and how to recognize early warning signs. We also offer you tips to extend spindle bearing life.

The Importance of Spindle Bearings in CNC Machines

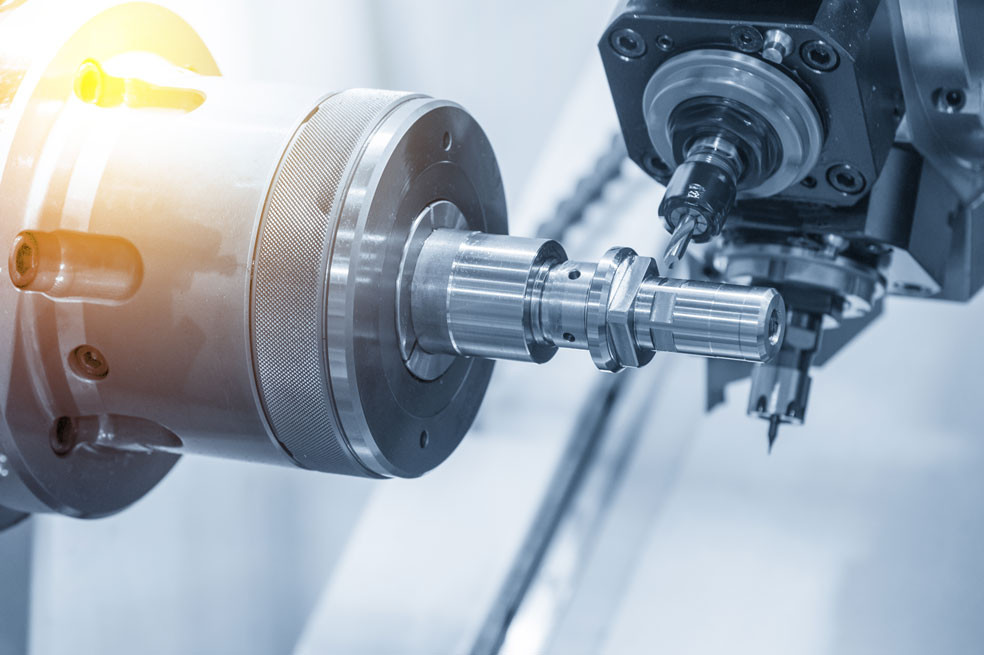

Spindle bearings (also known as Precision Angular Contact bearings) are important components of all CNC machines. Spindles are the primary rotating elements of the application, responsible for driving cutting tools or workpieces at high speeds with precision and consistency, ensuring smooth machining action. The bearings, especially spindle bearings located in the spindle head, are an integral part of the spindle and directly influence machining accuracy and tool performance.

A failed bearing not only affects production but can also lead to costly repairs and damage to other spindle components. Even if the bearing is yet to fail, a fault with the bearing or its seat will impact its performance and the level of accuracy and precision it can offer, which could affect the quality of the overall CNC machine's work. This is why it is essential to choose the correct bearings based on speed, load capacity, lubrication type, and operating conditions to give you the best performance and longevity. When CNC spindle troubleshooting, look out for these potential issues that could be symptoms of a bad spindle bearing.

1. Inadequate Lubrication

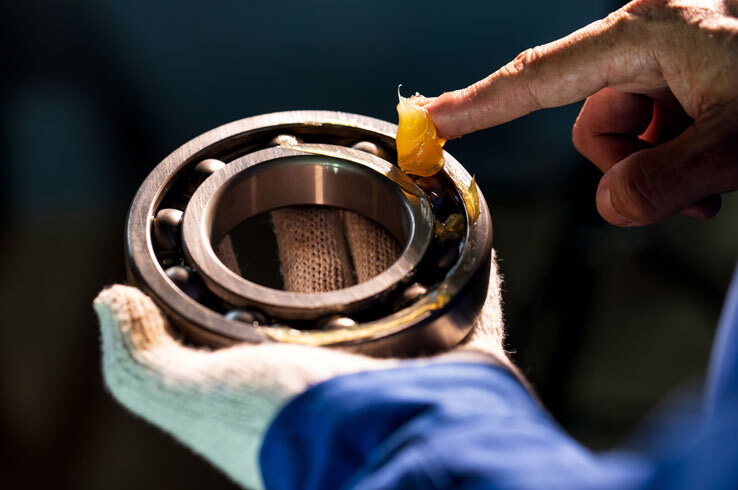

Lubricating spindle bearings is essential because it reduces friction and minimizes wear on the rolling elements and raceways. If there is not enough lubrication on the Precision Angular Contact Bearings, it can result in excessive wear and increased friction, leading to overheating, internal damage, and premature failure. Some bearings come with factory pre-lubrication, but you must regularly check and maintain lubrication levels according to the manufacturer’s guidelines. Over-lubrication can also be a problem because excess grease or oil can create churning, leading to increased internal friction.

Selecting the right lubricant for your spindle bearings is key to extending the life of your bearings and preventing the risk of failure. SKF Lubricants are known for their high-performance formulations that provide excellent wear resistance. They have a range of lubrication products tailored for different spindle speeds, loads, and environmental conditions.

2. Contamination

Contamination can mean a lot of things when it comes to spindle-bearing failure. The precision angular contact bearings may accumulate dust particles, dirt, or metal shavings from the surrounding environment. Dust and debris getting into the bearing housing or raceways is a big problem as it causes abrasion, increases friction, and leads to pitting or premature wear of the bearing surfaces. Using vacuum dust collectors can help reduce the presence of contaminants and prevent them from settling into the spindle assembly.

When troubleshooting the CNC spindle, it’s important to check for all types of contamination. Contamination could also be caused by an oil or coolant leak from a damaged component somewhere in the lubrication or cooling systems. Seals or gaskets may fail, allowing oil or coolant to enter the spindle housing, washing away lubrication and increasing the risk of corrosion or internal contamination.

Air filters could become clogged or ineffective over time, allowing unfiltered particles to circulate in the machine environment. Regular maintenance of air filters helps prevent contamination-related failures.

3. Incorrect Usage

Improper use of CNC machines, such as operating the spindle at speeds beyond its limits or applying too heavy loads, can put too much pressure on the spindle bearings and lead to failure. Disregarding operating guidelines puts unnecessary stress on the spindle bearings, reducing their lifespan. When buying precision angular contact bearings, it’s important to understand their limits. Equally, you should know the rest time spindles require after a duration of continuous running. For example, after 8 hours of operation, air-cooled woodworking spindles should be rested for a minimum of 1 hour before being restarted to allow for proper cooling.

4. Temperature

Excessive heat is detrimental to spindle bearings as it can degrade lubricants and cause thermal expansion, resulting in compromised performance and bearing failure in extreme cases. To prevent this, you must use effective cooling methods such as liquid cooling systems or properly timed spindle warm-up and cool-down cycles.

5. Warm-Up and Cool-Down Procedures

As just mentioned, warm-up and cooling procedures are a critical part of the CNC machining process, but are often overlooked when CNC spindle troubleshooting. In terms of warm-up, starting the CNC machine at full speed can cause thermal shock and uneven expansion. At the end of the operation, cooling the CNC machine down too quickly can lead to internal condensation which can result in moisture buildup, leading to corrosion and lubricant degradation inside the spindle bearings. For both warm up and cool down, follow the manufacturer's instructions to gradually increase or decrease spindle speed.

6. Misalignment

Even a slight misalignment during bearing installation or spindle assembly can cause a lot of problems to your CNC machine. Properly aligned spindle bearings are fundamental to the precision of your CNC machine, and also prevent uneven wear to the rolling elements and raceways. You should periodically check the alignment of the spindle and bearing housing to make sure everything is correctly in place.

7. Overloading

Precision angular contact bearings can typically withstand high radial and axial loads, but they do have limits. If you go beyond the specified load capacity, the bearing elements can lose their shape and become fatigued, leading to premature failure. If you know that your machine has been overloaded, check the shape of the bearing raceways for deformation or brinelling is a symptom of a bad spindle bearing.

8. Poor Bearing Selection for the Application

A common mistake that results in bearing failure is made before the machine is ever in operation. Installing the wrong type of bearing for your CNC machine will result in poor performance and potentially catastrophic spindle failure. If you are unsure which bearing type suits your application, seek advice from specialists who understand spindle requirements and can recommend the best bearings based on speed, load, and environmental conditions.

How Can Spindle Failures Be Prevented?

Here are some tips to help prevent you from experiencing bearing failure in your CNC machine in the future:

Follow manufacturer guidelines: Ensure that you adhere to recommended operating limits, including speed and load capacity.

Frequently check alignment: Inspect spindle and bearing alignment regularly to prevent excessive vibrations and uneven wear.

Properly lubricate spindle bearings: Use the appropriate lubricant and apply the correct amount at the recommended intervals.

Thorough operator training: Educate machine operators and maintenance staff on proper spindle handling, including warm-up and cool down procedures.

Implement contamination control: Keep the CNC machine and its surroundings clean, use dust collection systems, and regularly check seals and air filters.

Explore Spindle Bearings at Quality Bearings Online

Quality Bearings Online is home to a wide selection of high-performance spindle bearings designed for CNC machines. Our range of spindle bearings, or precision angular contact bearings is suitable for various application requirements. We also have a team of experts who know exactly which bearing type you need for your CNC machine to operate smoothly, minimizing the risk of unexpected failure. We can also advise you on the best lubrication for your specific spindle type.

If you have any further questions about spindle bearing failure, please get in touch and speak to one of our experts who will happily advise you on the best options for your machinery.